THE RIGHT SLOT-DIE COATER

THE RIGHT SLOT-DIE COATER

How to choose your slot-die coater

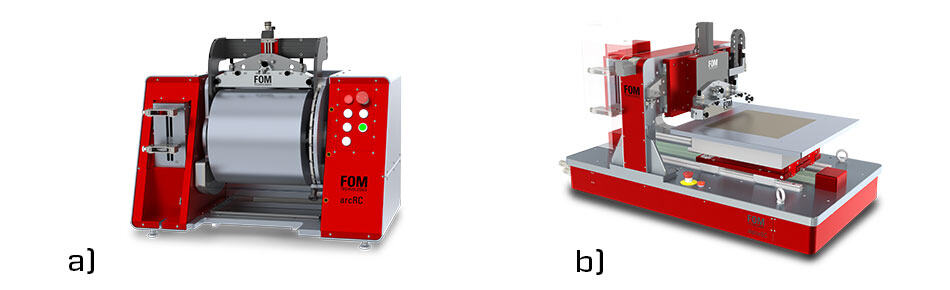

Figure 1 – FOM Slot-die coating product portfolio. (RC series – Roll Coaters, SC series – Sheet Coaters, R2R – Roll-to-roll series)

On the other hand, our benchtop sheet coaters (SC) represent the ultimate combination of precision and versatility as a lab-scale coating platform for almost any thin film application. Their sheet-based, heated vacuum chuck design enables coating on flexible or rigid substrates, simulating both R2R and sheet-to-sheet (S2S) processes in a compact form factor with easy sample handling for subsequent drying and analysis.

What type of material do you want to coat?

What type of substrate do you want to use?

Are you exploring new materials or devices?

The discovery of new materials usually happens when only small quantities are available. Nevertheless, researchers often want to deposit these new materials onto a substrate. Our slot die heads come with minimal dead volumes together with a pump back function which reduces the wastage of the precious new material to negligible. Still, selecting a small slot die head is preferable to have minimal material consumption when coating.

Researchers frequently want reproducible results over as many and as large substrates as possible when testing new devices. Larger slot die heads can be selected for these cases, coating substrates with width up to 500 mm or even larger for industrial purposes.

Are you looking for industrial applications?

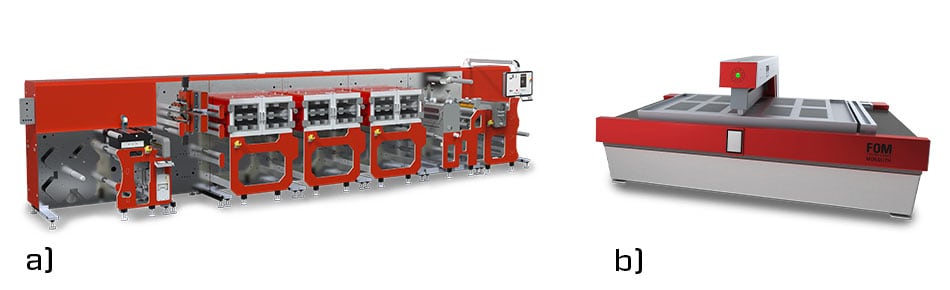

One of the main advantages of doing your R&D development with FOM equipment is that the transition to industrial-scale occurs seamlessly, reducing the cost and time required for technology scaling considerably. Furthermore, we at FOM can support not only your R&D development but your industrialisation process through our advanced equipment, namely the monolithSC and modulo R2R products.

Figure 4 – Industrial FOM slot-die coaters: a) FOM moduloR2R – your solution to flexible, roll-to-roll coating; b) FOM monolithSC – your large area solution for a sheet to sheet processes.

Download the FOM Technologies Product brochure

Fill in your information and click download to access the pdf.