Power-to-X

Power-to-X

Power-to-X in brief

Power-to-X (also known as PtX or P2X) is a collective term for energy conversion technologies that turn electricity from wind, water, or solar into an energy carrier (“X”). It is an umbrella term for different ways of generating energy, including Power-to-Gas, Power-to-Liquid, Power-to-Fuel, Power-to-Chemicals, and Power-to-Mobility. Power-to-X schemes are particularly useful in energy systems with high shares of renewable generation and/or fluctuating renewable sources.

Power-to-X technologies can be used to reduce greenhouse gas emissions in heavy transportation vehicles, ships, and air traffic by producing synthetic kerosene from electricity. The most promising concept is Power-to-Gas which can provide significant amounts of hydrogen or synthetic methane utilizing excess electrical power from renewables to produce a gas fuel. Other Power-to-X concepts include Power-to Heat which works either by resistance heating or via a heat pump and Power-to-Liquids which adds carbon dioxide to hydrogen to produce ammonia, methanol, or kerosene.

Chemistry researcher works at a low-temperature electrolysis testing station in the hydrogen research area at the Energy Systems Integration Facility (ESIF). (Photo by Werner Slocum / NREL)

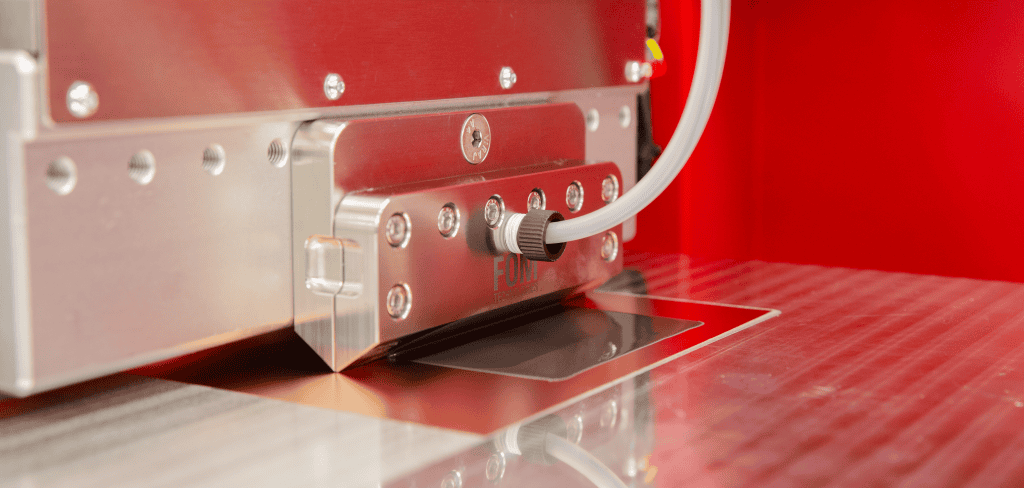

Slot-die coating used in the production of Power-to-X technologies

Slot-die coating is a coating technology for the application of a variety of liquid chemistry solutions of inks or slurry, onto substrates of various materials such as glass, metal, paper, fabric, or plastic foils. It is part of a family of techniques known as pre-metered deposition where the final film thickness is dependent upon the rate at which a solution is delivered. It is a scalable technique with potential for large-scale production of high-added-value thin films. It can be used to deposit optical coatings, corrosion-resistant materials, nanomaterials, and various membrane types for fuel cell production.

Slot-die coating has many applications in Power-to-X technologies. It has been used in fuel cell production, such as two-layer slot-die coating and drying studies of PEM fuel cells. It has also been used to enable the industrial production of electrodes for HT-PEM fuel cell systems due to the high suitability and performance of the slot-die-coated electrodes.

The superior control over the coated layers provided by the slot-die method makes it an efficient alternative to blade-coating and other conventional methods of deposition. FOM coating machines are equipped with the FOM coating software that allows the user microliter control of the ink or slurry over the full coating width for all rheology ink types. The results obtained from lab-scale FOM slot-die coating systems such as FOM arcRC or FOM alphaSC are easily scalable to FOM sigmaR2R or FOM moduloR2R providing higher line speed capability while offering uniform continuous coating or patch coating.

The future of renewable energy is in your hands. We can help you convert the clean energy of tomorrow into the power of today.

Researcher coats a fuel cell catalyst layer onto carbon-paper diffusion media using gravure coating, for a Roll-to-Roll research web-line manufacturing project. (Photo by Dennis Schroeder / NREL)

Let’s talk about scaling your Power-to-X research

One of our experts will reach out and help you find the most suited equipment based on your needs.

We are ready to assist you

Martin Kiener, CIO & Founder

Power-to-X technologies

Power-to-X technologies are essential in achieving a carbon-neutral society and they are one of the most effective ways of storing energy from fluctuating renewable sources. Power-to-X solutions can be divided into two categories: Those that use electricity as a direct power source (e.g., Power-to-Heat and Power-to-Mobility) and those that produce synthetic fuels (e.g., Power-to-Gas, Power-to-Liquid, Power-to-Fuel, and Power-to-Chemicals). The relatively low efficiency of the latter limits their employment to areas in which the direct use of renewable sources of energy is either barely possible or not feasible.

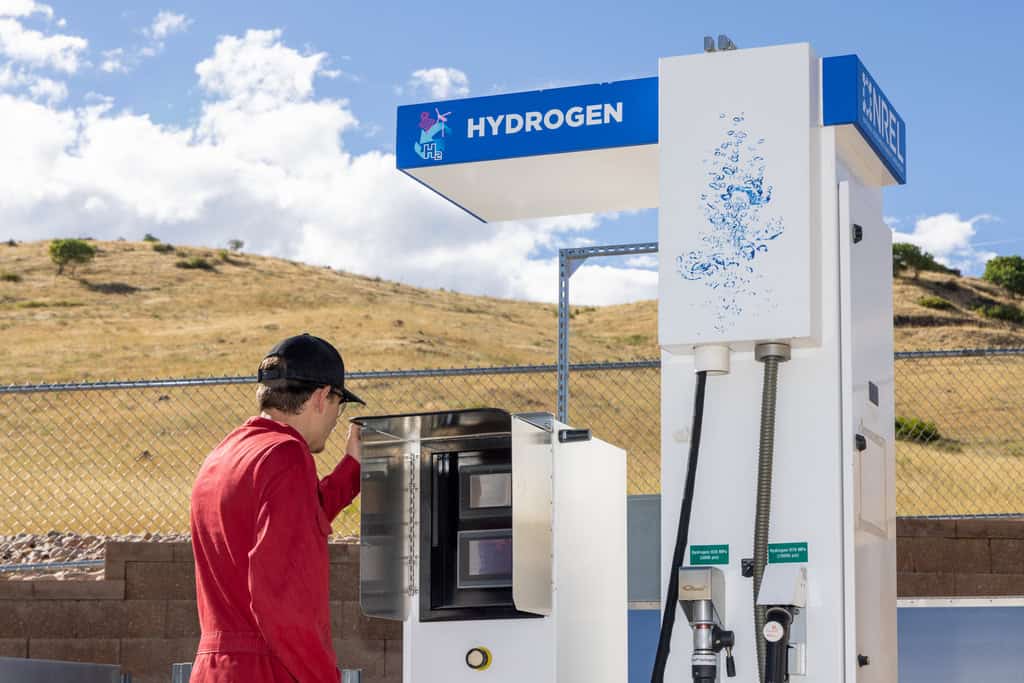

Mechanical engineering researcher for hydrogen production, power, and storage, looks over the 750kw electrolyzer in the Energy Systems Integration Facility (ESIF) at the National Renewable Energy Laboratory (NREL). The electrolyzer produces hydrogen from electricity and water. Collins performs techno economics and data analysis for medium and heavy duty vehicles, and coordinates aviation business opportunities for NREL. (Photo by Werner Slocum / NREL)

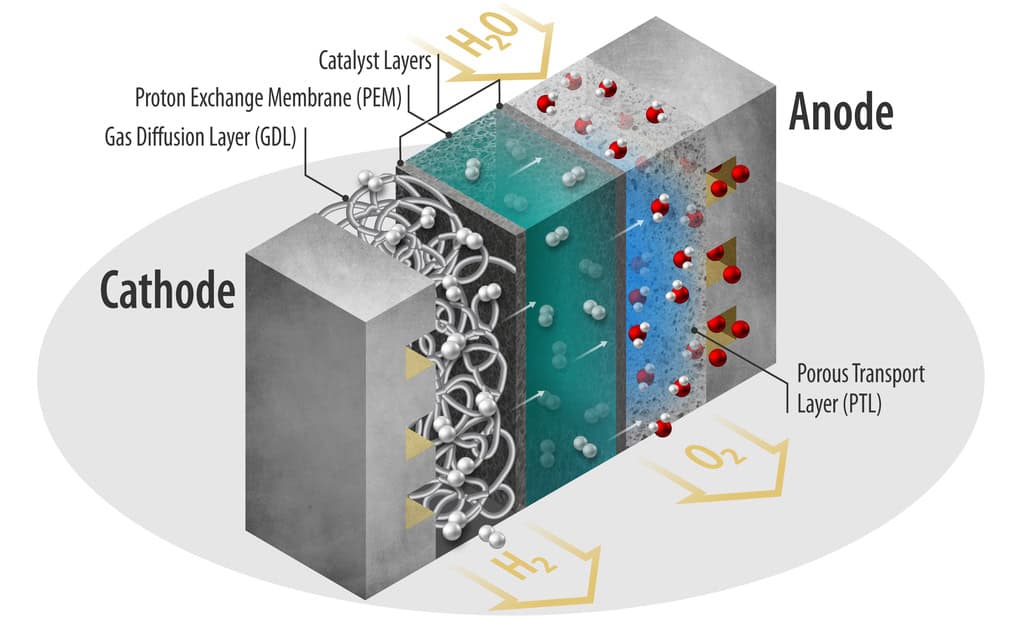

One of the core technologies behind Power-to-X is electrolysis where water is split into hydrogen (H2) and oxygen (O2). Then, Hydrogen can be used directly as a final energy carrier or it can be converted into, for example, methane, synthesis gas, liquid fuels, electricity, or chemicals.

Power-to-X advantages

Power-to-X technologies are many electricity conversions, energy storage, and reconversion pathways that use surplus electric power, typically during periods where fluctuating renewable energy sources are available. These technologies allow for the decoupling of power from the electricity grid for use in other sectors such as transport or chemicals.

The benefits of Power-to-X solutions include balancing the gap between variable renewable energy generation and load, improving the feasibility of renewable power projects by maximizing energy utilization, and facilitating the replacement of fossil fuels with carbon-neutral alternatives. Power-to-X technologies help extend the use of energy coming from renewable sources to sectors that are not directly connected to the electricity grid such as transportation, heating, and cooling. Additionally, Power-to-Heat involves contributing to the heat sector either by resistance heating or via a heat pump which can increase efficiency.

Numerous Power-to-X projects have already been put into service around the globe. Energy sources have a major impact on Power-to-X and almost half of the projects consider a supply by direct renewable energy technologies such as wind, water, or solar demonstrating their potential for helping to transition away from fossil fuels.

Power-to-X economics

The economics of Power-to-X technologies depend on factors such as continuous price decline of electricity from renewable sources and capital costs. Energy producers, utility companies, logistical solution providers, and large industrial consumers of energy are potential beneficiaries of these technologies. The potential market for Power-to-X solutions is expected to grow due to increasing demand for carbon-neutral solutions.

The potential market for Power-to-X technologies is estimated to reach 601-2,319 billion EUR by 2035. The global Power-to-X market is expected to grow at a compound annual growth rate (CAGR) of 9.8% between 2023 and 2033. In 2021, Europe held the largest market share in terms of revenue, while the Asia-Pacific region is expected to register the fastest growth in CAGR over the forecast period due to soaring power demand caused by rapid urbanization and industrialization. The transportation segment is anticipated to dominate the market in terms of end-use, driven by increasing demand for eco-friendly automobiles with reduced environmental carbon emissions.

The hydrogen facilities at NREL’s Energy Systems Integration Facility (ESIF). (Photo by Dennis Schroeder / NREL)

Power-to-x industry outlook

Power-to-X technologies provide the potential to reduce initial investment and increase process efficiencies, particularly in electrolysis.

The power and energy industry has significantly grown over the recent years and is expected to rapidly expand in terms of revenue share over the forecast period. Major players are focused on adopting various strategies such as mergers and acquisitions, product launches, collaborations, etc. to gain a competitive advantage in the market.

In Europe, industrial-based Power-to-X projects are of higher interest compared to other countries, with almost half (105) of all projects considering a supply by direct renewable energy technologies such as solar or wind energy sources. In terms of fuel production, Power-to-X is the most common field of application in Europe with a 37% share of all projects, indicating that the development of Power-to-X technologies is progressing quickly and will continue to do so in the near future.

More on Power-to-X

Want to learn more about our products?