Products

Products

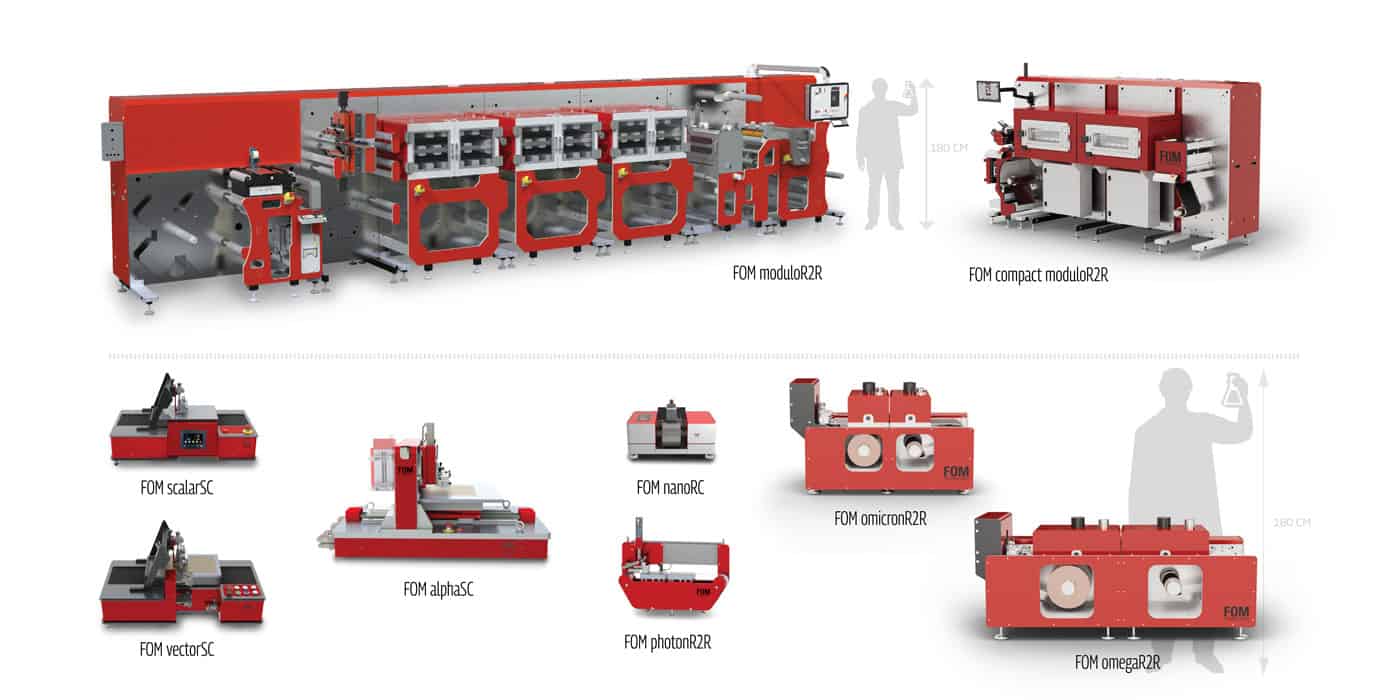

Machines and equipment

FOM Technologies provides high-quality state-of-the-art slot-die coating machines produced in Scandinavia. Our cutting edge equipment enables researchers, scientists and professionals, to discover, develop and commercialise new functional materials for a cleaner and more sustainable world. We strive to ensure that our products always are innovative, reliable and cost-effective.

Roll-based

Sheet-based

Roll-to-roll

Slot-die heads

FOM Technologies state-of-the-art slot-die heads have been designed to provide outstanding coating properties and simple compatibility with FOM coating machines. Variable head sizes and viscosity ratings combined with flexible shim thickness and stripe pattern options provide access to a user-friendly, high-quality coating platform for a broad range of thin-film applications.

Our slot-die heads contains comprehensive solutions for lab-scale applications, and the larger slot-die heads has been developed to support pilot-scale installations and beyond. Made from some of the hardest steel in the world, our slot-die heads are the product of a world-class manufacturing process, offering low dead volume, excellent flow properties, and treatment for robust chemical resistance. Following years of innovation and optimization, we are proud to offer slot-die heads that meet the needs of professional materials researchers above all else.

Steel Series

PEEK Series

STATE-OF-THE-ART SOLUTIONS

We provide high-quality state-of-the-art slot-die coating equipment produced in Scandinavia.

This ensures that our products are cutting-edge, innovative, reliable, and cost-effective.

Want to learn more about our products?