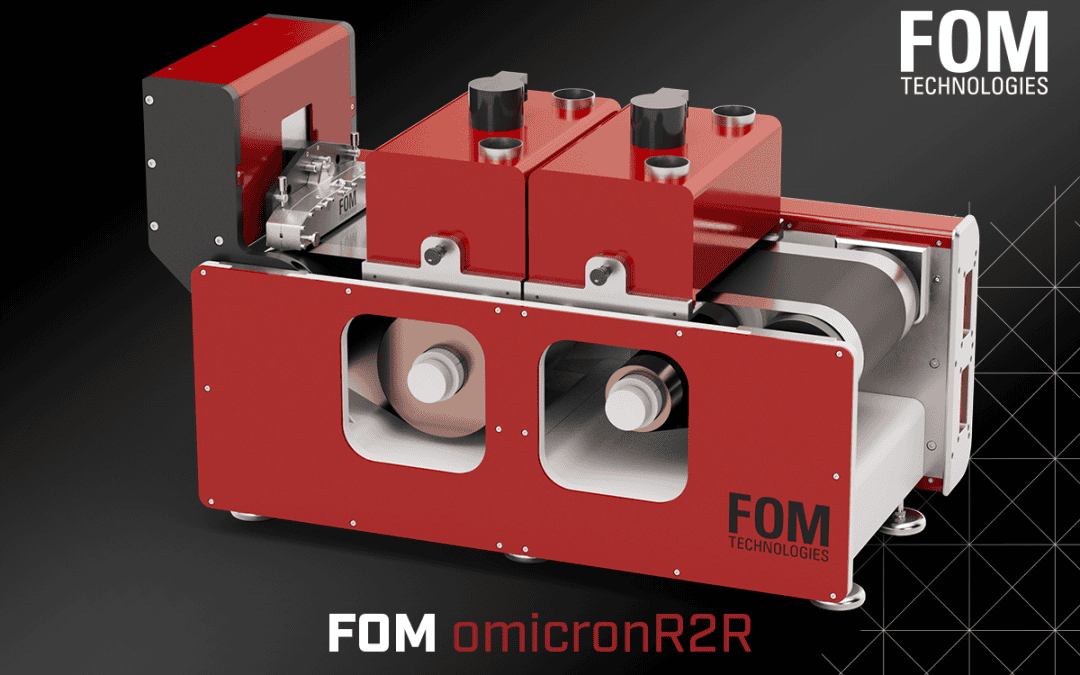

FOM Technologies launches FOM omicronR2R: A roll-to-roll coater designed for controlled environments

FOM Technologies proudly announces the release of the FOM omicronR2R—a compact, high-precision roll-to-roll slot-die coater developed for advanced lab-scale research.

Engineered for seamless integration into glove boxes and fume hoods, the system enables safe, stable, and reproducible coating of air and moisture-sensitive materials. With its modular, reconfigurable design and micron-precision slot-die control, FOM omicronR2R supports a wide range of solution viscosities, film thicknesses, and drying protocols, offering full control over film morphology and uniformity.

Its intuitive control software allows precise tuning of coating and drying parameters, accelerating material screening and reducing development time. Compatible with various ink chemistries and substrate types, FOM omicronR2R is ideal for thin-film R&D in perovskite PVs, batteries, printed electronics, and flexible devices.

Designed to perfect your coating process before scaling up.

“With the launch of the FOM omicronR2R—our second product release this year—we’re proud to respond directly to the needs of our customers. This compact platform expands our roll-to-roll coater lineup and brings high-precision deposition into the heart of the lab. We see it as a key step in making FOM Technologies a standard presence in every lab where thin-film coatings of reactive materials play a critical role.” – Michael Stadi, Group CEO, FOM Technologies

Highlighted features:

- Designed for controlled environments

- Modular & scalable architecture

- Precision coating technology