Coating high-viscous electrode slurries

Coating high-viscous electrode slurries

The push for thicker electrodes in battery research

In the ever-evolving field of battery technology, researchers are constantly pushing the boundaries to enhance the performance and efficiency of lithium-ion batteries, solid-state batteries, and new material research. One critical area of focus is the coating process of high-viscous battery electrode slurries, particularly when aiming to maximize the thickness of electrodes without compromising their overall performance.

Challenges of coating high-viscous slurries

Maximizing energy density in thick electrodes

Coating with FOM offers a solution

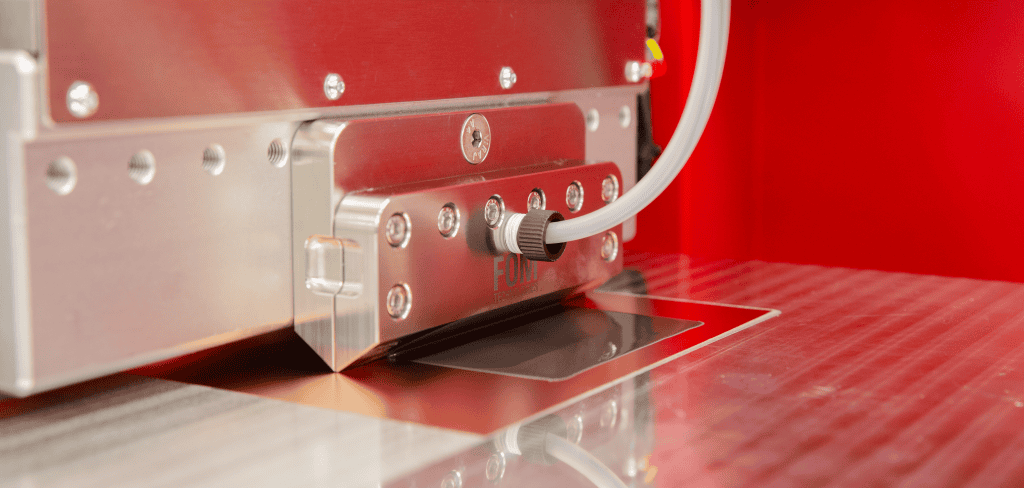

FOM Technologies slot-die coating machines are designed to meet these challenges head-on. Equipped with state-of-the-art ovens and user-centric software, these machines provide unparalleled control over the drying process, which is crucial when working with thick, high-viscous slurries. The ability to set different temperatures in each oven ensures that the solvent evaporates evenly, leaving a uniformly dried electrode layer.

The drying process is particularly critical when dealing with high-viscous slurries. If a coat is dried too quickly, the binders and conductive additives may migrate to the surface, resulting in a layer with poor electrical contact with the substrate and reduced overall performance. Additionally, improper drying can lead to uneven porosity, affecting the lithium-ion batteries’ efficiency and durability.

Enhancing battery technology with precision coating

Using FOM Technologies’ slot-die coaters, researchers and manufacturers gain full control over the coating process, effectively addressing the challenges of coating high-viscous battery electrode slurries. Whether developing coin cell batteries, small pouch cells, or large pouch cells, these machines ensure optimized electrode quality, enhanced energy density, and the advancement of modern battery technology.

Read more on the topic

Download the FOM Technologies Product brochure