Edge elevation in battery electrode coating

Edge elevation in battery electrode coating

Tackling edge formation when coating battery electrodes

Precision and material efficiency are paramount in battery research and development, particularly with lithium-ion battery electrodes. One of the persistent challenges that researchers face is the edge elevation issue while coating thick, high-viscosity electrode layers. Edge formation, particularly side-edge elevation, also known as heavy edge, occurs when the edges of the coated substrate become elevated, creating an uneven surface that can be costly, time-consuming, and wasteful. This seemingly small imperfection can have significant repercussions throughout the battery production process, especially during the crucial stages of calendaring and cutting.

The costly impact of coating defects like edge elevation

Challenges during calendaring due to heavy edge

How FOM slot-die coaters address and improve edge quality

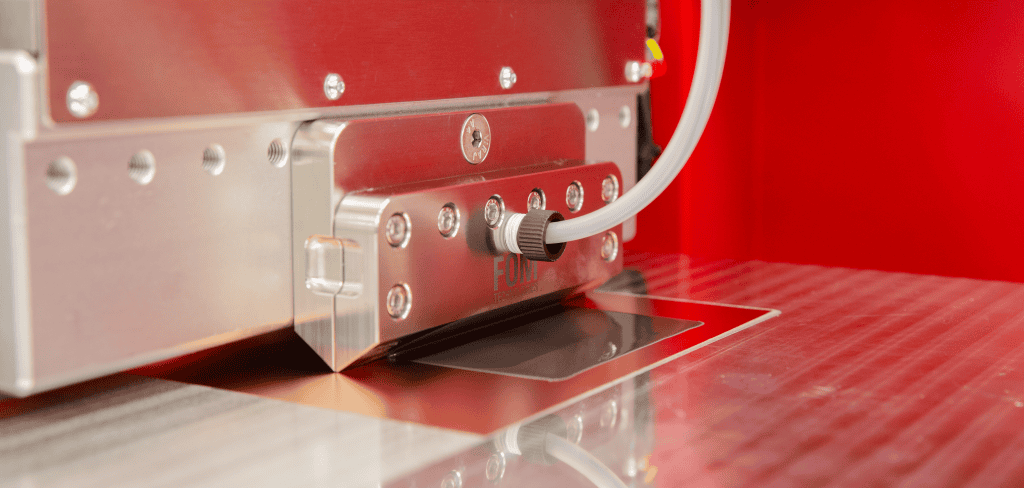

One of the key advantages of slot-die coating over traditional blade coating is the non-contact nature of the process. In slot-die coating, the coating head never touches the substrate. Instead, the meniscus guide—a critical component of the slot-die head—directs the slurry onto the substrate with remarkable precision. This process occurs extremely close to the substrate, essential in preventing edge elevation. By ensuring equal pressure across the lip of the slot-die head and carefully controlling the coating speed and pump flow rate, FOM Technologies’ machines achieve a uniformly distributed coating with perfectly even edges, significantly improving edge quality.

This level of control is difficult to achieve with other coating methods, such as blade coating/doctor blade, where the physical contact between the blade and substrate can easily lead to variations in pressure and, consequently, coating defects like heavy edges.

Expert support and custom solutions

At FOM Technologies, we understand that each research project is unique, and challenges can arise even with the most advanced equipment. If you ever encounter issues with elevated edges or other coating defects in your coating process, our team of experienced scientists is here to help. We offer personalized support, including live or online workshops, to help you optimize your coating parameters and achieve the best possible results with your FOM Technologies slot-die coater.

By choosing a FOM Technologies roll-to-roll coater, you’re not just investing in cutting-edge equipment—you’re gaining access to a wealth of expertise and support that will help you overcome the challenges of battery technology electrode coating, enhance edge quality, and push the boundaries of your research—whether you’re working on coin cell batteries, small pouch, or large pouch cells.

Read more on the topic

Download the FOM Technologies Product brochure