FOM Talks:

Irene Park, a Ph.D. at the University of Calgary

FOM Talks:

Irene Park, a Ph.D. at the University of Calgary

The role of slot-die coating in reducing food waste

A cleaner, greener, and more sustainable world is not only about energy storage and harvesting; these approaches extend to all aspects of our lives. To learn how FOM Technologies slot-die coating machines can help people differentiate spoiled from unspoiled foods, we talked with Irene Park, a Ph.D. candidate at the University of Calgary, about her research in organic materials. These materials can react when exposed to certain gases and light, and the chemical reaction causes them to change color. The aim of Dr. Park’s work is that these materials will one day function as sensors to indicate whether the food in commercialized packaging is spoiled.

Why is monitoring food quality so important?

In the EU alone, nearly 59 tons of food waste are generated yearly, with an associated market value estimated at 132 billion euros.¹ This amounts to more than 130 kilograms per inhabitant. The statistics indicate that around 10% of food products made available to EU consumers are possibly wasted. When we talk about food waste, we refer to edible food intended for human consumption that is instead discarded or left to expire.

From the Eurostat statistics, we also learned that food waste is estimated to account for about 16% of the total greenhouse gas (GHG) emissions within the EU food system. On top of this, research compiled by Our World in Data estimates that where food production is responsible for approximately 26% of global GHG emissions,² food waste alone accounts for 6% of the world’s total emissions.³

Globally, the Food and Agricultural Organization of the United Nations estimates that about 1/3 – amounting to approximately 1.3 billion tons – of all food produced for human consumption is lost or wasted.⁴ Wasted food is a combination of wasting all the energy and water it takes to grow, harvest, transport, and package it to be ready for consumption. And if food ends up in the landfill to rot, it produces methane—a greenhouse gas even more potent than carbon dioxide.⁵

By reducing food waste, the EU’s Sustainable Development Goals can be achieved while simultaneously fighting climate change and saving money for farmers, companies, and households.

Sensors made of organic material

As we talked to Irene Park, a Ph.D. candidate in Chemistry, we found out that, according to her, one of the biggest concerns of food production and distribution companies is determining whether the food product is fresh for consumption. So, she asked: “What if we could find a way to indicate whether food is still fresh and, in turn, potentially reduce the amount of wasted food globally?”

To explore the use of slot-die coating machines and equipment to innovate in organic materials and food packaging, we sat down with Irene Park, whose research project is supervised by Dr. Gregory Welch, a Professor of Chemistry at the University of Calgary, Canada.

Park was initially a bioscience student, minoring in nanoscience. However, during her studies, she started to gain interest instead in the field of material chemicals.

“I am currently working on synthesizing organic materials, typically sensors, for green processability in food packaging. This material, which I’m working with, can be processed from green solvents, non-halogenated or alcohol solvents, and coated on a slot-die coating machine. It can then be readily used as a sensor, for instance, in food packaging,” Irene Park explains as she discusses her research project.

Park explains the term “green solvents,” which refers to solvents designed to have a minimal environmental impact. Working with green solvent processible materials has proven to be a relatively easy way to mix the ink slurry, including Park’s material, which is then coated on different substrates.

The project is funded by NSERC – Green Electronics Network. It aims to reduce food waste by formulating a dual-sensing material that can easily be coated and used in different food packaging. This material signals humans when food has gone bad by changing its color.

Park continues: “When various foods go bad, they start to produce a volatile gas. This gas can react with my material, making it change color. The colorimetric sensor system, which goes from green to yellow and red, indicates whether the food is safe to consume.”

She further explains how the material is dual-sensing. UV rays can cause food to degrade faster, so Park’s materials can also function as UV sensors. This way, they can additionally be used in organic photovoltaics, another field of interest to Park herself.

Slot-die coating as a technology to combat food waste

We at FOM Technologies enable researchers, scientists, and other lab professionals to produce and study new functional organic materials for a cleaner, greener, and more sustainable world. We do this through our machinery, equipped with extreme precision and scalability, thus enabling reproducible test results in research and development.

With the FOM machines, researchers can easily change the temperature and speed of the slot-die head, allowing experimentation with different ink formulations, throughput, and drying time and eventually ensuring a uniform, thin film.

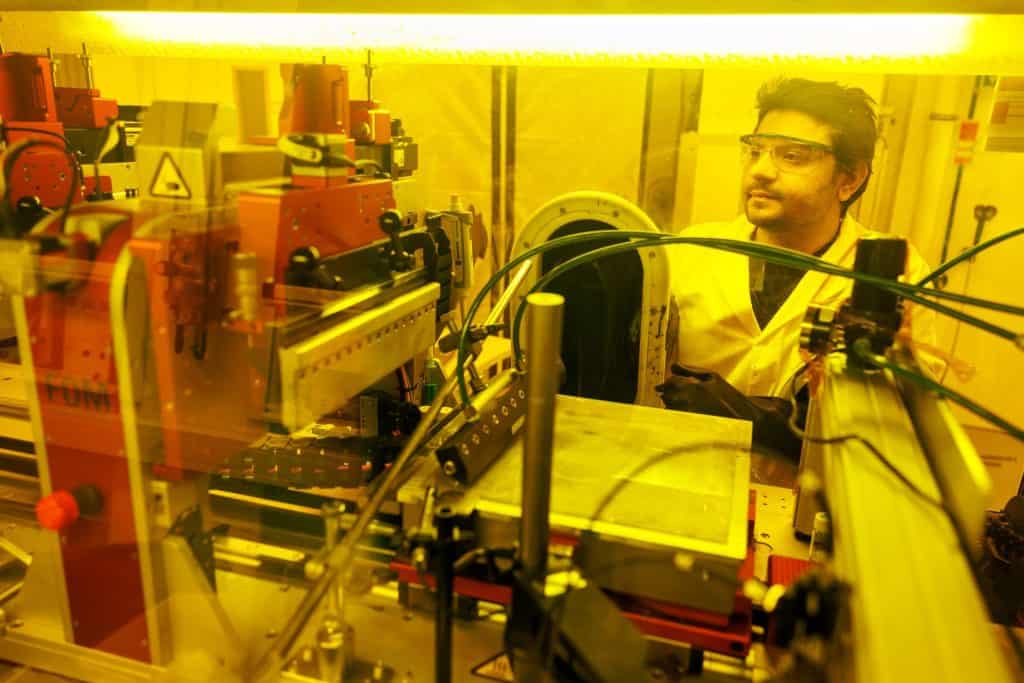

Irene Park adds that the laboratory at the University of Calgary uses its FOM slot-die coating machines daily for different experiments produced by various teams and disciplines within the campus.

“If you think about the commercialization aspect of my project, the readily available printing of beautiful thin film on large substrates is a big part of the future. I think the FOM equipment has helped our research group a lot–both in terms of the dual sensing food packaging material and organic solar cells.”

Coating dual-sensing materials

The dual-sensing materials developed by Irene Park not only indicate food spoilage but also serve as UV sensors, which has significant implications for organic photovoltaics (OPVs). OPVs are a type of solar cell that uses organic materials to convert sunlight into electricity. The ability of these materials to sense UV exposure can enhance the efficiency and longevity of OPVs by preventing degradation caused by UV rays. This dual functionality makes the material highly versatile and valuable in multiple applications, potentially leading to more sustainable food packaging solutions and improved solar energy technologies.

FOM slot-die machines in academia

The University of Calgary purchased a FOM vectorSC slot-die coating machine in 2019 intending to study organic photovoltaics in solar cells. The machine is used largely by the science faculty and chemistry department, both overseen by Dr. Gregory Welch.

We at FOM have been following Dr. Welsh’s department’s innovation journey and publications. His name also appears in many of the scientific research articles in the organic photovoltaics category at the bottom of this page. All these studies have benefitted from using FOM slot-die coating machines.

We are incredibly proud to have provided such a state-of-the-art slot-die coating machine to many academic faculties. We are also impressed and surprised by the amazing projects the future scientists in these universities devise to create a better world for us all.

Integrating innovative technologies, such as slot-die coating and dual-sensing organic materials, presents a promising path toward a more sustainable future. Researchers like Irene Park and institutions like the University of Calgary are paving the way for significant environmental and economic benefits by addressing critical issues like food waste and advancing renewable energy solutions. As scientists and researchers continue to explore and develop these technologies, the potential to make impactful changes in our daily lives becomes increasingly tangible. With the support of companies like FOM Technologies, the vision of a cleaner, greener world is not just an aspiration but an achievable reality.

Our business is built on believing in the vast benefits, reproducibility, and scale-up possibilities of slot-die coating, whether for solar photovoltaics, batteries, Power to X, or whatever you’re working on. Please reach out to us if we can help you.

Read similar posts

Download the FOM Technologies Product brochure