FOM Talks:

QD Solar Inc.

FOM Talks:

QD Solar Inc.

Working towards large-area photovoltaics

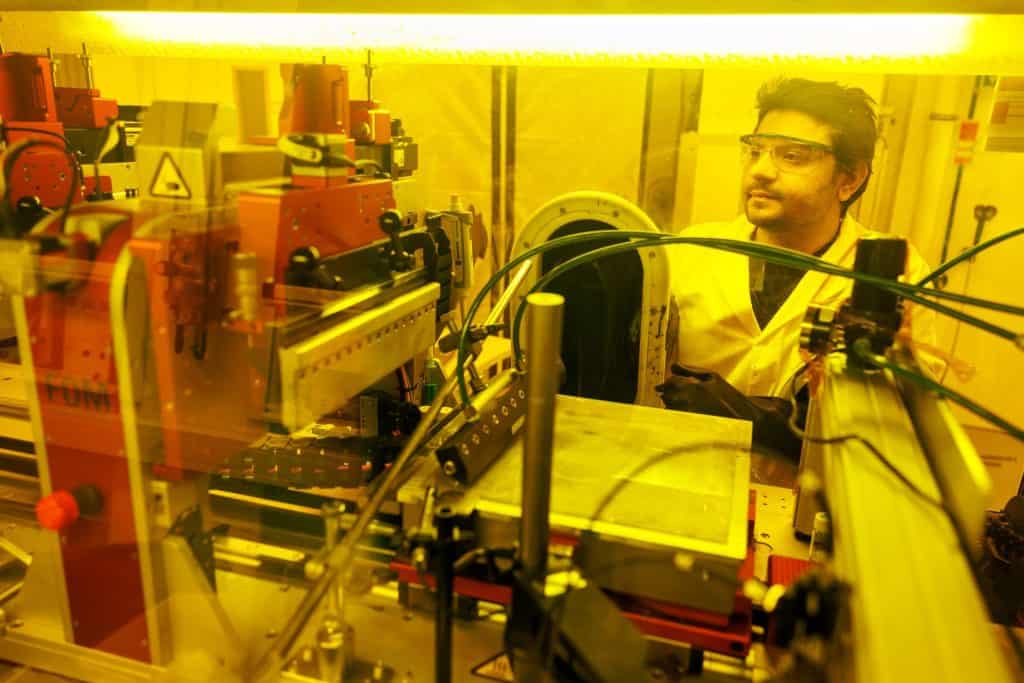

At FOM Technologies, we aim to build strong relationships with our customers and make sure we aid in the best possible way to help them succeed in their goals. In May, we met up with QD Solar Inc. to talk about their latest record-breaking result, their use of FOM equipment, and the potential of slot-die coating in cutting-edge green technology in general.

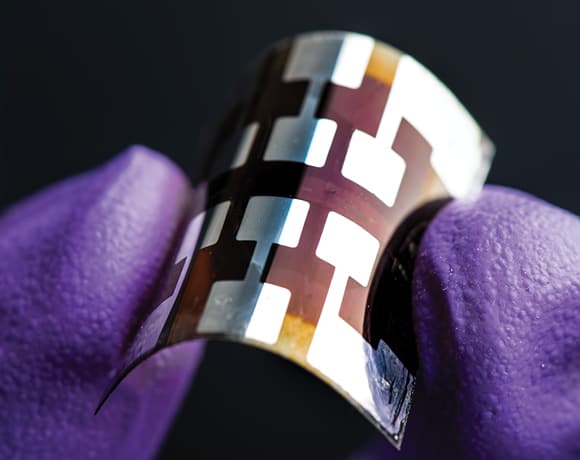

Toronto-based QD Solar is a next-generation solar materials company developing advanced multilayered solar photovoltaics. In February 2023, their slot-die coated, manufacturing-ready, single-junction perovskite solar cells reached a 3rd party-validated power conversion efficiency (PCE) of 23.2%, one of the highest efficiencies ever reported in this materials class fabricated with scalable and industry-relevant techniques.

“QD Solar has been working towards slot-die coated large-area photovoltaics since 2021. Around February this year, the QD Solar team managed to reach 23.2% PCE for slot-die coated solar cells and 24% PCE for spin-coated”, says Dr. Sjoerd Hoogland, co-founder and CTO of QD Solar. Usually, there’s a great discrepancy between the numbers of slot-die coated and spin-coated records, but in this case, these new numbers are close and mean a significant step for QD Solar applying slot-die coating.

“This advancement shows that we’re almost at parity”, he continues as he explains that some of the main questions they’re trying to answer at QD Solar revolve around bringing large-area manufacturing up to speed with small-area manufacturing and also bringing those numbers into a commercial role through the clean energy market.

The importance of precision

Shifting from lab-scale to extensive areas and creating impressive results beyond what you might see in any academic lab requires proper and reliable equipment. We are proud to say that the 3rd party validated slot-die coated record was set on the FOM vectorSC machine, allowing for easy control and a seamless workflow.

“One of the things you want in a slot-die coater is the fact that one person can have a set of conditions they use on one machine and someone halfway across the world can take those exact same conditions that you’ve developed, hit go, and it’ll be the same. You don’t see that in spin-coating where it can come down to something as small and simple as how you hold for example a pipette dispensing the perovskite precursor solution onto the substrate, i.e. the angle of it. It can end up having a huge influence on the results,” Dr. Richard Pettipas explains, who joined the QD Solar team as a chemist in December 2022.

“The technology from FOM feels responsive and organic in use,” he continues. At FOM, we provide high-quality state-of-the-art slot-die coating equipment which enables researchers, scientists, and professionals to discover, develop, and commercialize new functional materials. We always ensure that our products are innovative, reliable, and cost-effective in use.

A brighter future ahead

As we work collaboratively towards a greener future, we will probably see an increased demand for high-performance yet low-cost solar cells and solution manufacturing. Setting these new records could potentially have a massive impact on climate issues.

“It’s amazing to think that we could potentially cover the whole world in solar panels and call the energy crisis fixed. It’s a utopian thought, of course. Still, QD Solar’s latest results have shown that these things are becoming more feasible or accomplishable through technology,” Dan Shea, CEO of QD Solar says.

So, what is the future of QD Solar?

Of course, we can’t predict the future. But if you ask Dr. Sjoerd Hoogland, the future of slot-die coating is bright. At QD Solar, they’ve already shown impressive results and record-breaking numbers. The goal is to further improve the performance combined with long-term stability. To reach this, they’re currently seeking funding and investments to scale up their fabrication to a commercial level.

“We’re starting to approach parity between slot-die coating and spin coating, so let’s go all the way and see parity between the two. Given the remarkable process control of a slot-die coater, I can see slot-die coating surpassing spin coating, and I think one of the reasons why it hasn’t is simply because more people are doing spin coating,” Hoogland says. He continues to explain how time, research, and investment into spin coating technology is currently surpassing that of investment in slot-die coating.

“Comparing both technologies, slot-die coating is actually the better approach for large-area coating with exceptional homogeneity. I think, over time we’ll see the gap between the two technologies closing, and eventually, we’ll probably see slot-die coating come out ahead.”

Are you interested in learning more about the evolution of PV? Then you can read more in this blog post on the role of slot-die coating in the future of photovoltaics.

Below is a plot showing the single-junction perovskite solar cell efficiency evolution (all sizes) by deposition method used for the perovskite absorber. As notable exceptions, we included slot-die coating efforts with the utilization of FOM tools. Certified results were preferred when available.

Download the image as a high-res PDF.

Our business is built on believing in the vast benefits, reproducibility, and scale-up possibilities of slot-die coating, whether it be for solar photovoltaics, batteries, Power to X, or whatever you’re working on. Please reach out to us if we can help you.

(Photos of slot-die coated solar cell by QD Solar)

More on solar

Download the FOM Technologies Product brochure