Innovation in hydrogen technologies

Innovation in hydrogen technologies

Unlocking the Power of Hydrogen

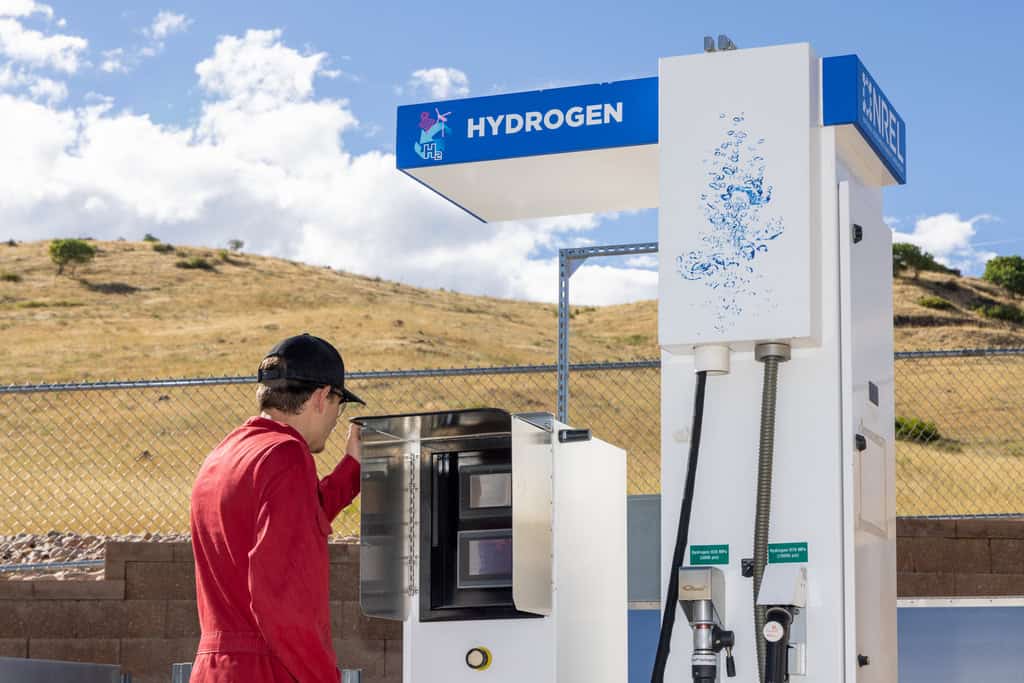

The demand for clean, renewable energy is bigger than ever, and “for climate experts, green or renewable hydrogen (made from electrolysis of water powered by solar or wind) is indispensable to climate neutrality.”¹

According to The Future of Hydrogen report by IEA²

- Hydrogen can help tackle various critical energy challenges. It is more and more a realistic alternative to meaningfully reduce emissions in transport, chemical fabrication, and iron and steel extraction refining and processing, among others.

- Hydrogen is versatile, and it is an energy vector. It can be transported, stored, and converted to other forms of energy or fuels. With that in mind, the gas industry is looking to a new horizon of possibilities.

- Hydrogen can enable renewables to provide an even greater contribution by storing surplus energy from renewables to match future energy demand.

Hydrogen can be used much more widely, replacing fossil fuels in sectors such as transport, buildings, and power generation. It is absolutely necessary to fulfill the European Green Deal Commitment to become the world’s first climate net-zero emissions continent by 2050.³

Three main types of Hydrogen

- Grey hydrogen is made from natural gas. The process emits CO2.

- Blue hydrogen is also made from natural gas, with CO2 emissions reduced by using carbon capture and storage (CCS) systems, which are not 100% efficient. CCS are called “priority breakthrough technology” in the European Green Deal.

- Green or renewable hydrogen is powered by renewable energies where hydrogen is produced by splitting water into hydrogen and oxygen in a process called water electrolysis.

There are few other colors for other strategies, and there are no assigned colors for hydrogen from biomass, nuclear, or different varieties of grid electricity.

According to a new joint study of hydrogen technology patents by the European Patent Office (EPO) and the International Energy Agency (IEA)⁴, innovation in hydrogen is shifting towards low-emission solutions, with Europe and Japan in the lead, the United States losing ground in the period 2011–2020, and hydrogen-related innovation from R. Korea and P.R. China are only starting to emerge at the international level.

In the mentioned period, the international patent families (IPFs) in hydrogen technologies can be distributed across three technology segments of the hydrogen value chain:

- Production

- Storage, distribution, and transformation

- End use.

About half of IPFs were related to hydrogen production

The Revealed Technology Advantage Index (RTA) indicates a country’s specialization in terms of hydrogen innovation relative to its overall innovation capacity (filed patents). Japan, Korea, and China have an RTA in all three hydrogen value chain segments. EU member states are leaders in hydrogen patenting with 28% of the global share (including Germany with 11% and France with 6% of the global total).

Innovation in established hydrogen technologies is dominated by the European chemical industry, also leading the development of electrolysis and fuel cell technology. It follows a trend in innovation related to alternative, low-emission methods for hydrogen production.

It all anticipates a boom in electrolysis technology.

From an economic and ecological production of green hydrogen by water electrolysis point of view⁵ for alkaline water electrolysis (AEL), proton exchange membrane water electrolysis (PEM), and solid oxide electrolysis (SOE), the total specific energy demand is largely similar. Dynamic operation will be a major characteristic, but the necessity and the extent of dynamic operation will depend on the carbon footprint of the electricity used. Is stated by the authors of the cited paper.

They also stated that AEL seems to be the most suitable technology for the production of low-carbon hydrogen with fluctuating renewables due to lower investment costs and lower specific energy demand. In this technology, the alkaline conditions at the electrodes are compatible with non-precious metal catalysts other than the platinum group metal catalysts non requiring either high-purity gases.

Fuel cells

Fuel cells are devices that electrochemically convert the chemical-free energy of gaseous or liquid reactants into electrical energy continuously or vice versa.⁶ The concept has been known since 1839 when Christian Friedrich Schönbein recognized and described the appearance of “inverse electrolysis”⁷

Heat engines and electrochemical energy storage devices (mainly batteries) existed side by side in the late nineteenth and early twentieth century, but the abundance of fossil fuels has later driven the development of combustion engines and turbines retarding the development of alternative energy conversion devices, such as batteries and fuel cells. It could well be that the expected end of the “oil age” may also go along with an increasing importance of alternative energy conversion devices, among which fuel cells have the potential to play an important role.⁶

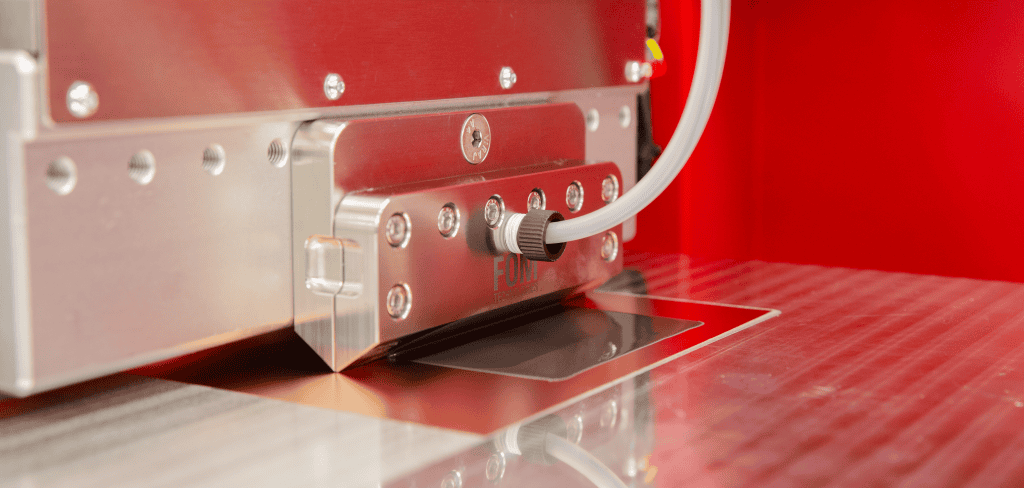

In the next years, the world will see more innovation across various technologies, including hydrogen technologies. At FOM Technologies, we pride ourselves on helping our customers move from old coating techniques. As a part of our services, we provide different levels of workshops and specialized training courses and give consultation on how our customers can slot-die coat their materials using FOM machines.

FOM machines are ideal for scaling up your research findings in order to validate and demonstrate your technology. Scaling up is one of the most important steps for FOM’s innovative startup customers to secure finance to continue their product development.

References

1) van Renssen, S. The Hydrogen Solution? Nat. Clim. Chang. 2020, 10 (9), 799–801.

2) IEA (2019), The Future of Hydrogen, IEA, Paris

3) A European Green Deal. European Commission, 2020

4) Hydrogen patents shift towards clean technologies with Europe and Japan in the lead, 2023

6) Fuel Cells. Selected Entries from the Encyclopedia of Sustainability Science and Technology. Editor Klaus-Dieter Kreuer. ISBN 978-1-4614-5785-5

7) Schönbein CF (1839) X. On the voltaicpolarization of certain solid and fluid substances, Philosophical Magazine Series 3, 14:85, 43–45.

Read more on the topic

Download the FOM Technologies Product brochure